FLOW METER

WHAT IS A FLOW METER?

A FLOW METER is a device used to measure the volume or mass of a gas or liquid. Flow meters are referred to by many names, such as flow gauge, flow indicator, liquid meter, flow rate sensor, etc.

depending on the particular industry. However, they all measure flow. Open channels, like rivers or streams, may be measured with flow meters. Or more frequently, the most utility from a flow meter and the greatest variety of flow meters focus on measuring gasses and liquids in a pipe.

Improving the precision, accuracy, and resolution of fluid measurement are the greatest benefits of the best flow meters.

Flowmeters consist of a primary device, transducer, and transmitter. The transducer senses the fluid that passes through the primary device. The transmitter produces a usable flow signal from the raw transducer signal. These components are often combined, so the actual flowmeter may be one or more physical devices.

Flow Meter Applications

- Chemical processing

- Wastewater processing

- Process control

- Lubrication systems

- Solar systems

- Drain lines

- Pump testing

Type of Flowmeter

- Electromagnetic

- Ultrasonic

- Turbine, Propeller, and Paddle Wheel

- Vortex Shedding

- Target

- Variable Area and Rotameter

- Orifice Plate, Open Channel, Flow Nozzle, Laminar, Venturi, and Pitot Tube

What type of flow meter is best?

There are no “universal” flow meters which are suitable for all applications. Selecting the proper technology for your application requires writing a flow specification which covers the use of the meter. There are usually trade-offs with each meter type, so knowing the critical specifications will be important.

Things you must know:

- What is the Gas or Liquid being measured?

- Minimum and maximum flow rates.

- What are the accuracy requirements?

- The fluid temperature and viscosity.

- Fluid compatibility with the materials of construction (See our materials compatibility guide)

- The maximum pressure at the location.

- What pressure drop is allowable?

- Is the meter mounted in a hazardous location where explosive gases may be present?

- Is the fluid flow continuous or intermittent?

- What type of output signal or readout do you need?

Flowmeters

Flowmeters indicate flow rate. The different sensors include a dial, in-line, ultrasonic, orifice plate, totalizing meters, variable area, venturi, or with switch output. The different designs of the flowmeters have a variety of applications.

Dial Flowmeter

Flow meters measure water, oil, gas or air flow rates. Applications include calculating required fill or drain times for tanks, water towers, backflow prevention, heat exchangers, and oil & gas equipment.

In-line flowmeters

In-line flowmeters are indicators for flow rate. Applications include deionized water flow, pickling, compressed gases, harsh environments, coolant lines, and industrial applications.

Orifice Plate

Orifice plate flow meters are differential pressure sensors for flow rate. Can be used with gases, liquids, corrosive, and high-temperature fluids. Applications include steam flow, boiler feedwater, and fluid flow rates in building water lines. Designed for use wherever there is an application for a conventional flow orifice plate.

Totalizing Meters

Flow sensors with flow totalizing capability. Models contain LCD displays. Ideal for industrial use in reverse osmosis water purifying systems. Applications include water treatment, cooling systems, irrigation and water utilities. Some models are designed for any pump, pressure, or gravity feed system

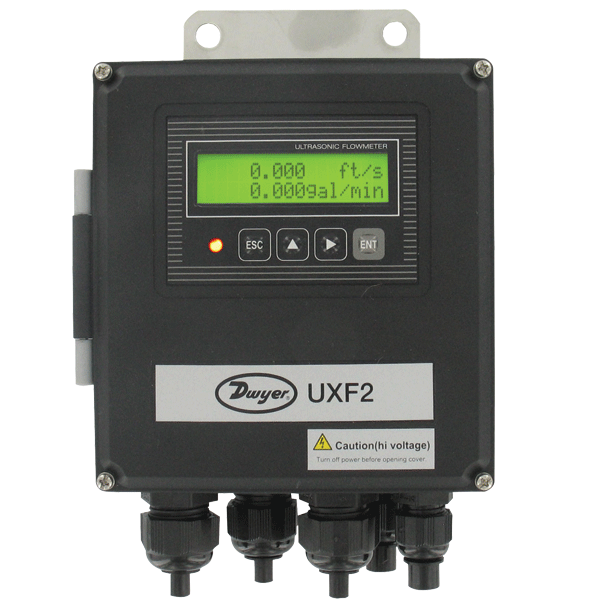

Ultrasonic

Ultrasonic flow meters are sensors with electrical transmission output. Models are compact and lightweight. The meters are easy to operate and are ideal for any flow measurement situation. There are options of clamp-on flowmeters for the ideal use of clean liquids containing no air bubbles such as pure water.

Variable Area

Tapered bore in-line indicators for flow rate. Ideal for high purity or corrosive liquid applications, gas and liquid applications, air samplers, and medical applications. Flowmeters are shipped assembled and ready for panel mounting.

With Switch Output

Flow indicators with an electrical contact output at a specific flow rate with switch output. Applications include chemical processing, wastewater processing, lubrication systems, drain lines, process control, and pump testing.

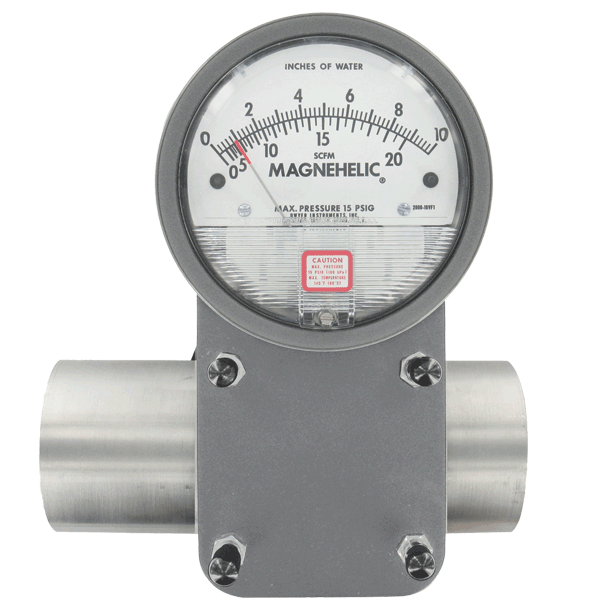

Venturi

Venturi in-line indicators for flow rate. The Magnehelic gage provides a large, clear and accurate display of your differential pressure reading. It is available in line sizes from 1″ to 4″ and can handle vacuum and pressure applications. Other applications include filter monitoring, clean room positive pressure indication, and fan pressure indication.

we can provide every type of flowmeter and deliver it to your company.

References:

Leave a Reply

Want to join the discussion?Feel free to contribute!